Rapier vs Air-Jet: What’s Driving the Loom Choice in 2025?

Share This

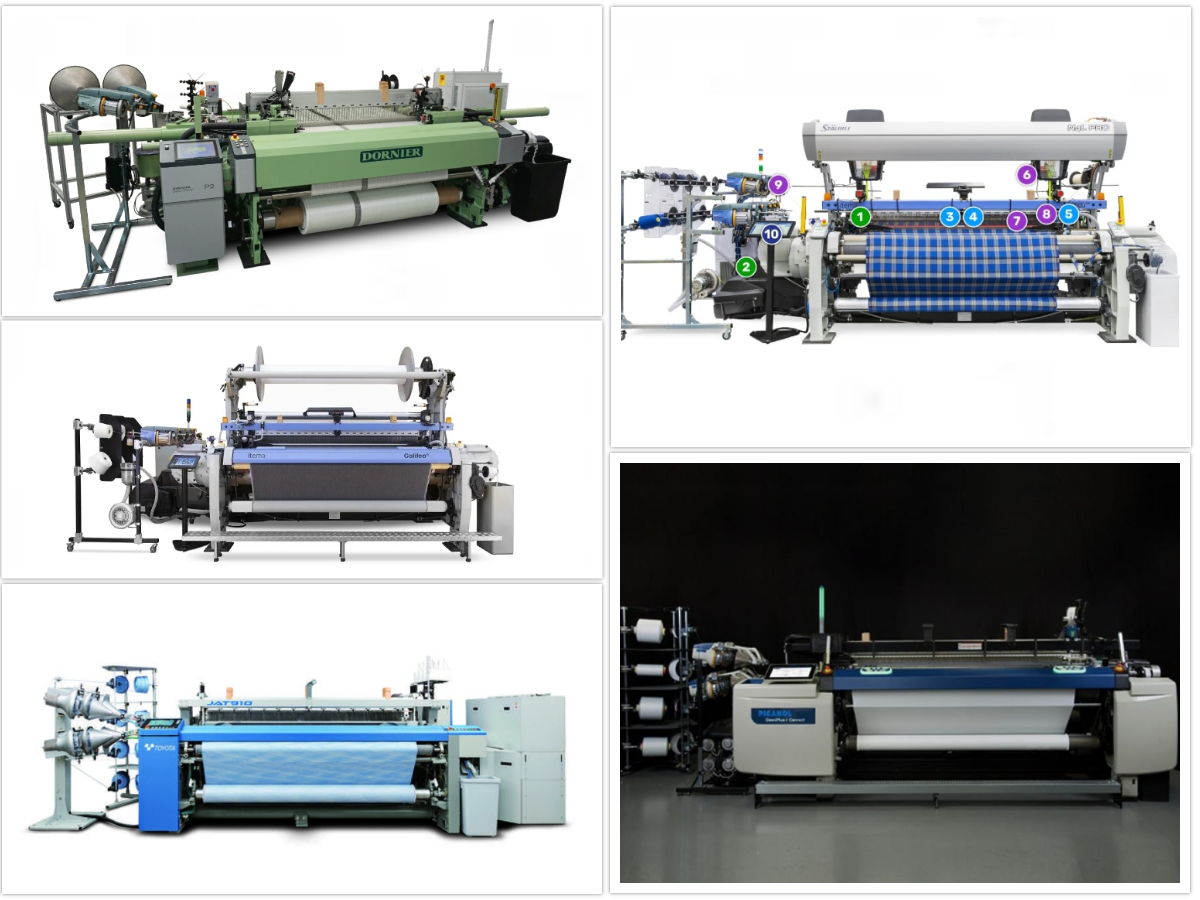

As Bangladesh’s woven sector pushes to reduce import dependency and climb up the value chain, the choice of weaving machinery has become more strategic than ever. In 2025, the debate between rapier and air-jet looms isn’t just about speed—it’s about flexibility, energy costs, yarn compatibility, and long-term ROI.

The Current Landscape

Bangladesh is heavily reliant on imported woven fabric, with nearly 60–70% of woven fabric needs met by foreign suppliers. While local mills are trying to scale up, weaving efficiency, versatility, and cost competitiveness are still key challenges. A critical decision point for investors and factory managers lies in selecting the right type of loom for their specific market goals.

Both rapier and air-jet technologies dominate the global weaving scene, but their value propositions are evolving.

Air-Jet Looms: Speed and Scale

Air-jet looms are favored for their high production speed—often exceeding 1000 picks per minute—and relatively low labor requirement. They are especially suitable for light to medium-weight fabrics like shirting, bedsheets, or lining materials.

- Pros:

- Exceptional speed and output

- Low vibration, smooth operation

- Easier to maintain with standard yarns

- Cons:

- High compressed air consumption, making them energy-intensive

- Limited yarn versatility (struggles with elastic, fancy, or coarse yarns)

- Sensitive to yarn quality—frequent stoppages with low-grade yarn

In Bangladesh, where energy costs and supply instability are major concerns, air-jet’s high energy footprint is increasingly seen as a constraint—especially in mills lacking efficient air compression systems.

Rapier Looms: Versatility with Precision

Rapier weaving machines like the Itema R9500EVO or Picanol OptiMax-i have become go-to options for mills prioritizing product range and design complexity.

- Pros:

- Handles a wider variety of yarns—elastic, fancy, high-twist, etc.

- Capable of producing high-value fabrics (denim, upholstery, jacquards)

- Lower energy consumption compared to air-jets

- Stable insertion even for weft yarns with low strength

- Cons:

- Slower than air-jet (typically 600–750 picks/min)

- Higher mechanical complexity

- Slightly more maintenance-intensive

For Bangladeshi mills looking to serve export buyers seeking diverse, fashion-oriented fabrics, rapier looms offer a long-term edge in terms of flexibility and innovation.

What's Driving the Choice in 2025?

In conversations with weaving experts and machinery suppliers, several emerging trends are influencing machine selection:

- Fabric Strategy: Mills targeting bulk commodity production are still leaning toward air-jets, but those moving into higher-end segments like value-added woven, stretch denim, or technical fabrics are adopting rapier looms.

- Energy Awareness: With energy prices rising and global buyers pushing for carbon neutrality, the energy-efficient profile of rapier looms is becoming a decisive factor.

- Workforce Skills: Rapier looms require slightly more skilled operators and maintenance staff. Factories with training capabilities or vendor support are more comfortable adopting this technology.

- Capex vs Opex Thinking: While air-jets may seem attractive for their throughput, rapier machines are winning favor among investors with a total cost of ownership mindset—factoring in yarn flexibility, waste reduction, and reduced air compressor costs.

The Hybrid Future?

Some of the most forward-looking mills are opting for a hybrid strategy—installing both types of looms to serve diverse market demands. This allows them to respond to seasonal orders, optimize energy use, and improve machine utilization based on the fabric being produced.

Final Thoughts

There is no one-size-fits-all answer—but the narrative is clearly shifting. In 2025, the smart money is on machines that offer long-term flexibility, lower environmental impact, and higher value output. For Bangladesh’s woven sector to thrive, embracing the right weaving technology is not just a production decision—it’s a strategic business move.